E-merchants, how to improve backorder management?

What is Backorder management

Backorder management is the process of handling orders for products temporarily out of stock. It’s a critical aspect of e-commerce operations, ensuring that customers’ needs are met even when inventory is low. However, managing backorders effectively requires careful planning and strategic execution.

Explanation: How backorders works

Backorders occur when a customer orders a product that is temporarily out of stock, and the seller accepts the order with the intention of fulfilling it when the product becomes available again. Below is a detailed breakdown of the usual process involved in handling backorders:

1- Customer places order: A customer places an order for a product that is currently out of stock. This could happen through various channels such as an online store, phone order, or in-person purchase.

2 – Seller acknowledges order: The seller acknowledges the order and informs the customer that the product is currently out of stock but is available for backorder. This acknowledgment typically includes information about the estimated time frame for when the product will be back in stock.

3 – Backorder confirmation: If the customer agrees to wait for the product to become available, the seller confirms the backorder with the customer. This confirmation may include details such as the expected arrival date of the product and any relevant terms or conditions.

4 – Payment processing: Depending on the seller’s policies, the customer may be required to pay for the backordered product upfront or upon shipment. In some cases, the seller may authorize the payment but not charge the customer until the product is ready to be shipped.

5 – Product restock: The seller monitors inventory levels and restocks the product when it becomes available from the supplier or manufacturer. This process could involve placing a new order with the supplier or waiting for existing orders to be fulfilled.

6 – Fulfillment and shipment: Once the product is back in stock, the seller fulfills the backordered items and prepares them for shipment. This may involve picking, packing, and shipping the product to the customer according to the shipping method selected during the order placement.

7 – Notification to customer: The customer is notified that their backordered product is now available and has been shipped. This notification typically includes tracking information so the customer can monitor the delivery status of their order.

8 – Product Delivery: The customer receives the backordered product according to the estimated delivery date provided by the seller. They can then use the product as intended or as specified in the original order.

It’s important for sellers to maintain clear communication with customers throughout the backorder process to manage expectations and ensure a positive experience. This includes providing regular updates on the status of backordered items and promptly addressing any concerns or inquiries from customers.

The Impact of Backorders on Supply Chains

Backorders, though common in the world of supply chain management, can have significant impacts on operations, customer satisfaction, and overall business performance. Let’s delve into how backorders affect supply chains:

- Disrupted Operations: Backorders can disrupt the smooth flow of operations within a supply chain. When a product is backordered, it can lead to delays in fulfilling customer orders, which in turn affects downstream activities such as shipping, distribution, and inventory management.

- Inventory management challenges: Managing backorders adds complexity to inventory management processes. It requires accurate tracking of stock levels, forecasting demand, and ensuring timely replenishment to minimize the impact on customer orders and maintain adequate inventory levels.

- Increased costs: Backorders can result in increased costs for businesses. Rush shipping or expedited production to fulfill backordered items may incur additional expenses. Moreover, maintaining safety stock levels to mitigate the risk of backorders ties up capital and increases carrying costs.

- Impact on customer satisfaction: Backorders can have a detrimental effect on customer satisfaction. Delays in fulfilling orders can lead to frustration and dissatisfaction among customers, potentially resulting in negative reviews, lost sales, and damage to the brand’s reputation.

- Lost revenue opportunities: Backorders represent lost revenue opportunities for businesses. Customers may opt to purchase from competitors if they cannot wait for backordered items to become available, resulting in missed sales and potential long-term loss of customer loyalty.

- Supply chain visibility and coordination: Effectively managing backorders requires strong supply chain visibility and coordination. Suppliers need to be informed promptly about backorders to facilitate timely replenishment, while accurate communication with customers is essential to managing expectations and minimizing disruptions.

- Long-term impacts: Chronic backorders can have lasting impacts on supply chain relationships and business viability. Suppliers may become reluctant to work with businesses that consistently experience backorder issues, leading to strained relationships and potential supply chain disruptions.

Key components of effective backorder management

Successful backorder management relies on several key components:

- Inventory visibility: Real-time tracking of inventory levels to anticipate and mitigate potential stockouts.

- Order prioritization: Strategic prioritization of backorders based on factors like order date and customer importance.

- Communication with customers: Transparent and proactive communication regarding the status of backordered items to manage expectations.

- Supplier integration: Seamless integration with suppliers for accurate forecasting and timely restocking.

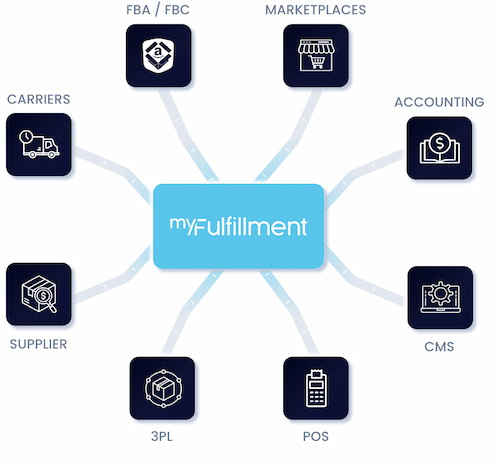

Boostmyshop myFulfillment: your ultimate backorder management solution

If you’re looking for a tool to improve your backorder management, we’ve the solution for you. Boostmyshop myFulfillment is a comprehensive SaaS software designed to manage backorders for e-commerce merchants. With its advanced features, myFulfillment empowers businesses to:

- Gain real-time visibility into inventory levels and stock movements.

- Automatically prioritize backorders and allocate available stock efficiently.

- Communicate seamlessly with customers, providing timely updates on backordered items.

- Integrate with suppliers to optimize restocking processes and minimize stockouts.

By leveraging Boostmyshop myFulfillment, e-commerce merchants can unlock a myriad of benefits, including:

- Enhanced customer satisfaction through transparent communication and timely updates.

- Significant time and cost savings through streamlined processes and automation.

- Opportunities for business growth and scalability with optimized backorder management.

Take Control of Your E-Commerce Success

In conclusion, mastering backorder management is essential for e-commerce success. With Boostmyshop myFulfillment as your trusted ally, you can navigate the complexities of backorder management with ease, ensuring satisfied customers and sustainable growth. Don’t let backorders hold your business back. Request a demo of Boostmyshop myFulfillment today and take the first step towards optimizing your e-commerce operations.